Volumetric Feeders

The volumetric feeders of GKS are primarily used for storing and metering cut and leaf tobacco or similar bulk solids, e.g. tea and herbs. Accordingly, these machines are designed FDA compliant and comply with the expanded standards of the tobacco processing industry.

Feeder F-Series

Brief Description

- providing of an uniform volumetric tobacco flow

- bottom belt conveyor with large side walls for a large stock of tobacco

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- elevating belt with pusher strips made of stainless steel, screwed

- belt drives controlled by frequency converter

- separately driven rotating doffer, height adjustable

- separately driven rotating brush, easy changeable

- roller scrapers (squeegee) with pull-out collecting tray

- transfer hood with 2 large maintenance flaps

Variants / Options

- chain-guided conveyor belts

- dust cover hood

- motion sensor system on the tensioning drum

- discharging belt conveyor attached to the transfer hood of the feeder

- more special designs on request possible

| Technical Data (Basic Design) | F-1100 | F-1200 | F-1400 | F-1600 |

|---|---|---|---|---|

| belt width (bottom and elevating belt conveyor): | 1,100 mm | 1,200 mm | 1,400 mm | 1,600 mm |

| effective width: | 1,050 mm | 1,150 mm | 1,350 mm | 1,550 mm |

| distance between axles - bottom belt conveyor: | 2,030 mm | 2,030 mm | 2,030 mm | 2,030 mm |

| distance between axles - elevating belt conveyor: | 2,580 mm or 3,280 mm | 2,580 mm or 3,280 mm | 2,580 mm or 3,280 mm | 2,580 mm or 3,280 mm |

| height of the side walls: | 1,000 mm | 1,000 mm | 1,000 mm | 1,000 mm |

| storage capacity: | approx. 1.7 m³ | approx. 1.9 m³ | approx. 2.2 m³ | approx. 2.5 m³ |

| total length: | approx. 4,400 mm or 4,700 mm | approx. 4,400 mm or 4,700 mm | approx. 4,400 mm or 4,700 mm | approx. 4,400 mm or 4,700 mm |

| total width: | approx. 2,170 mm | approx. 2,270 mm | approx. 2,470 mm | approx. 2,670 mm |

| height: | approx. 2,800 mm or 3,375 mm | approx. 2,800 mm or 3,375 mm | approx. 2,800 mm or 3,375 mm | approx. 2,800 mm or 3,375 mm |

| weight: | approx. 1,500 kg | approx. 1,600 kg | approx. 1,800 kg | approx. 2,000 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 3.8 kVA | 400 VAC, 50 Hz, approx. 3.8 kVA | 400 VAC, 50 Hz, approx. 3.8 kVA | 400 VAC, 50 Hz, approx. 3.8 kVA |

| PLC: | Siemens S7 | Siemens S7 | Siemens S7 | Siemens S7 |

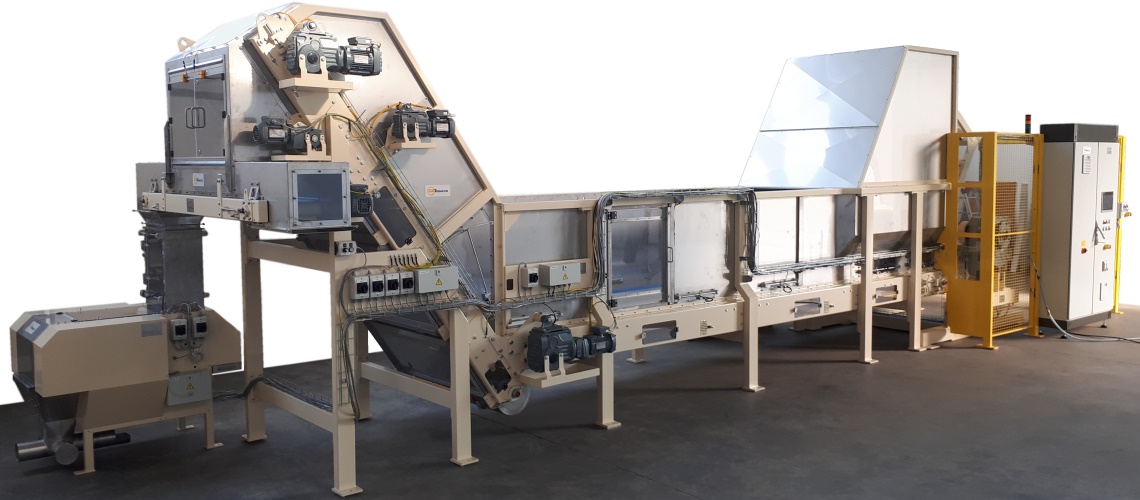

Feeder FS-Series (S-Shaped Belt Conveyors)

Variants / Options

- bottom belt conveyor with large side walls

- base frame and protective covering made of stainless steel

- belt drives controlled by frequency converter

- pusher strips made of stainless steel, screwed

- separately driven rotating brush, easy changeable

- roller scrapers (squeegee) with pull-out collecting tray

- motion sensor system on the tensioning drum

- adjustable deflectors for angular product transfers

- integrated permanent magnet in the transfer hood

- movable by means of steering rollers with double stop

- more special designs on request possible

Application Areas

- food and confectionery industry

- tobacco industry

Brief Description (Basic Design)

- providing of an uniform volumetric bulk flow

- base frame and protective covering painted

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- conveyor belt with welded on pusher strips

- separately driven rotating doffer, height adjustable

- dust collecting trays with sight windows on both sides

- transfer hood with large maintenance flap

Mini Silo MS-Series

Brief Description

- providing of an uniform volumetric tobacco flow

- large side walls for a large stock of tobacco

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- belt drive controlled by frequency converter

- 2 separately driven rotating doffers, adjustable

- roller scrapers (squeegee) with pull-out collecting tray

- transfer hood with 2 large maintenance flaps

Variants / Options

- discharging belt conveyor attached to the transfer hood

- separately driven rotating brush, easy changeable

- motion sensor system on the tensioning drum

- motion sensor system on the rotating doffers

- more special designs on request possible

| Technical Data (Basic Design) | MS-1100 | MS-1200 | MS-1400 |

|---|---|---|---|

| belt width: | 1,100 mm | 1,200 mm | 1,400 mm |

| effective width: | 1,050 mm | 1,150 mm | 1,350 mm |

| distance between axles: | 5,970 mm | 5,970 mm | 5,970 mm |

| height of the side walls: | 1,200 mm | 1,200 mm | 1,200 mm |

| storage capacity: | approx. 5.3 m³ | approx. 5.8 m³ | approx. 6.8 m³ |

| total length: | approx. 6,900 mm | approx. 6,900 mm | approx. 6,900 mm |

| total width: | approx. 1,600 mm | approx. 1,700 mm | approx. 1,900 mm |

| height: | depending on the application | depending on the application | depending on the application |

| weight: | approx. 2,000 kg | approx. 2,200 kg | approx. 2,500 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 3.1 kVA | 400 VAC, 50 Hz, approx. 3.1 kVA | 400 VAC, 50 Hz, approx. 3.1 kVA |

| PLC: | Siemens S7 | Siemens S7 | Siemens S7 |

Mini Feeder

Brief Description

- compact standard model for tobacco feeding

- feeding of up to 3 cigarette production machines (maker)

- belt drive controlled by frequency converter

- drive for rotating doffer controlled by frequency converter

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- optionally shorts add-back system

Required Conditions

- required minimum air velocity per suction connection of the mixing chamber: 21 m/s

- max. differences of air velocity of the suction connections of the mixing chamber: ±2.5%

| Technical Data | Mini Feeder E7 | Mini Feeder X3 |

|---|---|---|

| feeding (equals 100% maker efficiency): | 3 maker with max. 9,500 cig./min and 7 kg tobacco/min x maker continuous tobacco processing | 3 maker with max. 12,000 cig./min and 9 kg tobacco/min x maker continuous tobacco processing |

| maker feeding: | discontinuous (via flap sluice) | discontinuous (via flap sluice) |

| max. feeding capacity to the mixing chamber: | 3x 8 kg tobacco/min (equals 100% simultaneous factor) | 3x 12 kg tobacco/min (equals 100% simultaneous factor) |

| tobacco delivery: | to the metering tube; max. 26 kg tobacco/min | to the metering tube; max. 38 kg tobacco/min |

| length: | approx. 1,410 mm | approx. 1,860 mm |

| width: | approx. 1,010 mm | approx. 1,125 mm |

| height: | approx. 1,600 mm | approx. 2,100 mm |

| feeding pipe connections: | 3x ø125 mm x 2 mm (standard) | 3x ø125 mm x 2 mm (standard) |

| weight: | approx. 300 kg | approx. 385 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 1.7 kVA | 400 VAC, 50 Hz, approx. 1.5 kVA |

| PLC: | Siemens S7 | Siemens S7 |

Shorts Add-Back System

Brief Description

- system consists of Feeder F-300 and metering belt conveyor DFB-200 with integrated metering tube

- large feed hopper on the feeder for manual filling

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- installation of the system in line or at right angle shape

- special designs on request possible

| Technical Data (Basic Design) | Feeder F-300 | Metering Belt Conveyor DFB-200-1300 |

|---|---|---|

| belt width: | 300 mm | 200 mm |

| distance between axles: | 2,000 mm | 1,300 mm |

| delivery height: | 1,700 mm | 1,000 mm |

| dimensions (length x width x height): | 2,050 mm x 710 mm x 2,100 mm | 1,850 mm x 420 mm x 1,700 mm |

| weight: | approx. 250 kg | approx. 100 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 0.8 kVA | 400 VAC, 50 Hz, approx. 0.4 kVA |

| PLC: | Siemens S7 | Siemens S7 |