Belt Conveyors / Belt Weigher

Belt Conveyors SlimLine-Series

Application Areas

- food and confectionery industry

- tobacco industry

- pharmaceutical industry

Standard Features

- Clean-Design for easy cleaning

- side panels made of closed aluminium profile

- fixed center distance of the deflection pulleys

- omega drive station with belt tensioning

- drive via roller chain

- reversing operation possible

- belt sliding table made of stainless steel sheet

- height adjustable feet

Bulk Material Design

- side walls made of stainless steel sheet, equipped with sealing strips

- back wall made of stainless steel sheet, equipped with sealing strips

- feeding hopper made of stainless steel sheet

- transfer hood made of stainless steel sheet

Variants / Options

- side panels made of stainless steel

- geared motor with integrated frequency converter

- FDA approved conveyor belts and sealing strips

- rolling knife edge

- tensioning device at the end in case of long axis distances

- movable by means of swivel castors with double stop

- stripe brushes and flexible scrapers for belt cleaning

- coverings (fixed, removable or foldable)

- more special designs are possible on request

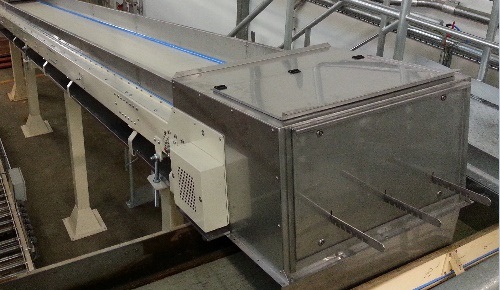

Belt Conveyors FBB-Series

Application Areas

- food and confectionery industry

- tobacco industry

Standard Features

- drive station with slip-on geared motor

- tensioning station

- base body and protective covers painted

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- belt sliding table made of stainless steel sheet

- adjustable constriction rollers with safety covering

- bottom strand idlers with support rings (PE) and safety covering

- transfer hood with large maintenance flap

Variants / Options

- base body and protective covers made of stainless steel

- geared motor with integrated frequency converter

- reversing operation possible (2 transfer hoods)

- omega center drive station

- buckling stations for concave or convex belt deflection

- driven rotating brush in half shell design

- driven rotating brush in segment design, quick change system

- stripe brushes and flexible scrapers for belt cleaning

- roller scrapers (squeegee) with pull-out collecting tray

- dust collecting sheets in the lower strand

- motion sensor system on the tensioning drum

- adjustable deflectors for angular product transfers

- coverings (fixed, removable or foldable)

- more special designs are possible on request

Belt Weigher DBW and RBW-Series

Application Areas

- food and confectionery industry

- tobacco industry

Standard Features

- drive station with slip-on geared motor

- tensioning station

- base frame and protective covering painted

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- adjustable constriction rollers with safety covering

- integrated metering tube with adjustable back wall

- transfer hood with large maintenance flap

Other Characteristics

- use as dosing belt weigher (DBW) or as registration belt weigher (RBW)

- dimensions according to customer requirements

- use of high-quality weighing technology (e.g. systems from Sartorius, Siemens Siwarex etc.)

Variants / Options

- base frame and protective covering made of stainless steel

- geared motor with integrated frequency converter

- driven rotating brush in half shell design

- driven rotating brush in segment design, quick change system

- stripe brushes and flexible scrapers for belt cleaning

- roller scrapers (squeegee) with pull-out collecting tray

- dust collecting sheets in the lower strand

- motion sensor system on the tensioning drum

- adjustable deflectors for angular product transfers

- coverings (fixed, removable or foldable)

- separately driven rotating doffer, adjustable

- movable by means of steering rollers with double stop

- more special designs are possible on request

Concave Bended Belt Conveyors FK-Series

Application Areas

- food and confectionery industry

- tobacco industry

Standard Features

- painted body

- product contacting parts are made of stainless steel

- FDA approved belts and sealing strips

- conveyor belt with welded on pusher strips

- dust collecting trays with sight windows on both sides

- transfer hood with large maintenance flap

Variants / Options

- body made of stainless steel

- geared motor with integrated frequency converter

- driven rotating brush in half shell design

- driven rotating brush in segment design, quick change system

- separately driven rotating doffer, height adjustable

- pusher strips made of stainless steel, screwed

- roller scrapers (squeegee) with pull-out collecting tray

- motion sensor system on the tensioning drum

- adjustable deflectors for angular product transfers

- integrated permanent magnet in the transfer hood

- movable by means of steering rollers with double stop

- more special designs are possible on request