News

"Wunderbar together!" - Delegation trip to the USA

Our Managing Director Christian Kummerfeldt and Sales Manager Ewald Roßkamp participated in a delegation trip organized by GACC Midwest - German American Chamber of Commerce of the Midwest, Inc.(GACC) to the US Environmental Circular Economy for Sustainability, which took place from June 5-9, 2023.

The trip started in Chicago with the Circular Economy Expert Conference on the 35th floor of GACC Midwest .Under the leadership of Ms. Katrin Geisler and the entire GACC team, the conference impressed with interesting, entertaining and knowledgeable daily schedules that united all participants in collective and individual activities. Especially the presentation event, which was attended by many participants important for GKS, were of great impact and resulted in promising networking conversations afterwards. We were very pleased with the lively and intensive response we received from the various partners during the individually prepared video conferences.

The same can be said about the follow-up trip to San Francisco, where Ms. Alexandra Banning and her GACC team responded to the specific wishes of the delegation members. California is aiming to be a pioneer in the USA when it comes to sustainability and the circular economy. The interaction between our machines and compostable films from our well-known partners seems to have left a special impression on the Californians and led to "scene applause" at various points for our presentation and the product samples presented.

The atmosphere among the delegation members was pleasantly relaxed and friendly. We are sure that many joint projects in the sense of sustainable circular economy in the transatlantic area will arise afterwards.

Many thanks to all those who contributed to this professionally prepared and executed trip!

A "wunderbares together" indeed!

Trade Show Review of Interpack 2023 in Düsseldorf, Germany

After 6 long years we look back to the Interpack 2023 in Düsseldorf with a lot of positive feedback and good impressions from our visitors. Thereby our visitors had the opportunity to examine the newly designed booth of GKS. For the redesign of our booth we received active support from the renowned designer Martijn Vogelzang from Antwerp.

From the large number of visitors, one could sense that we were obviously not the only ones who missed the fair.

The visitors showed special interest in our novelties concerning the processing of recyclable and compostable films on the packaging machines exhibited by us, which are already in use at some customers in this configuration. We would like to express our sincere thanks for the support of our partners from Domino, who provided us with a laser printer of the latest generation, as well as the packaging material manufacturers from SÜDPACK and SUPERSEVEN (rePAQ).

We received equally positive feedback on our exhibited sample bags, which were sealed with the latest ultrasonic sealing unit in our technical center and impressed with a unique and extremely good seam quality.

Intensive discussions were held, which we have hardly experienced in such a quality and variety in the past - and we are pleased to note: already 2 days after the end of the fair there are a lot of inquiries about our products and sample packs.

There can hardly be any greater praise for the trade fair team!

Newsletter I / 23

Packaging Machines

We are pleased to announce that we will soon be installing a new, highly specialized four-side-seal packaging machine type of FB-S at a German pharmaceutical company.

This company is a world leader in the development and manufacture of systems for absorbing drugs such as active ingredient patches and oral thin films.

With an output of up to 70 ppm in four lanes, transdermal active ingredient patches are packaged in the four-side-seal pouches. Special assemblies developed individually for this application ensure that the pharmaceutical products are manufactured efficiently and in a user-friendly manner.

In accordance with pharmaceutical industry specifications for product traceability, batch numbers, expiration dates and the like are printed using four fully integrated thermal transfer printers and subsequently verified by a camera system.

Accessories

Our newly developed roll lifter significantly facilitates film roll changes.

Secured by 2-hand operation, a roll of packaging material is picked up, for example, from a pallet and safely lifted to working height. Partial or empty rolls can also be placed back on a pallet.

Upgrade

In La Roche-Posay, France, an extensive modification was recently completed on two existing machines for four-side sealed pouches.

Cosmétique Active Production, , which belongs to the L'Oréal Group, produces pharmaceutical cosmetics for dermal application here.

Two production lines were each equipped with a GKS automatic secondary packaging system, which also has functions for product counting, automatic NOK rejection and sampling.

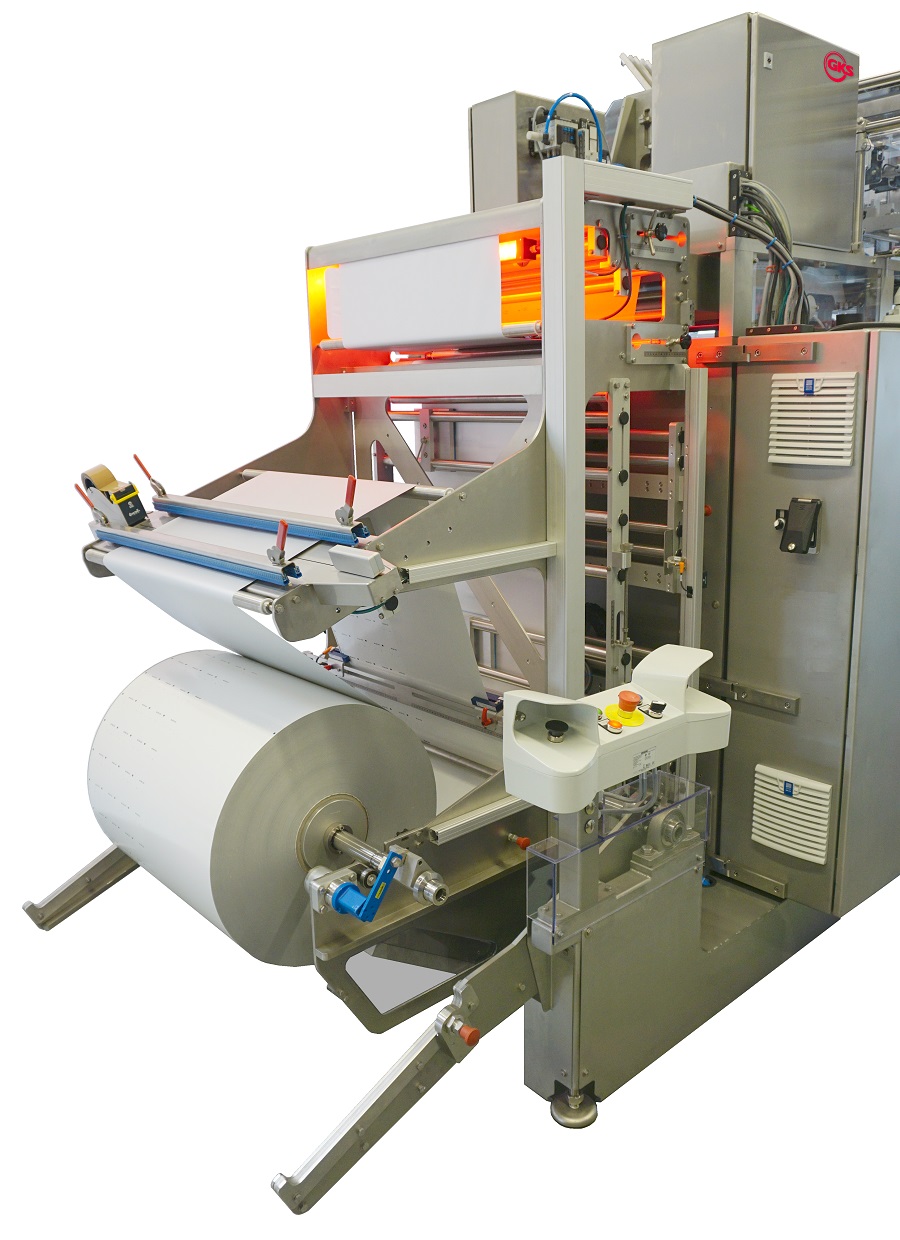

Ultrasonic Sealing

Constantly we're also developing further ultrasonic sealing units.

With the help of the previous prototype unit, extensive tests were successfully completed with conventional as well as with new, recyclable and compostable packaging materials.

A unique feature is the extremely good seam quality with a very wide seam.

Positive feedback from our customers on the samples produced confirm our decision to now manufacture a complete ultrasonic sealing system and integrate it into our demo form, fill and seal machine SB-L.

Sustainability

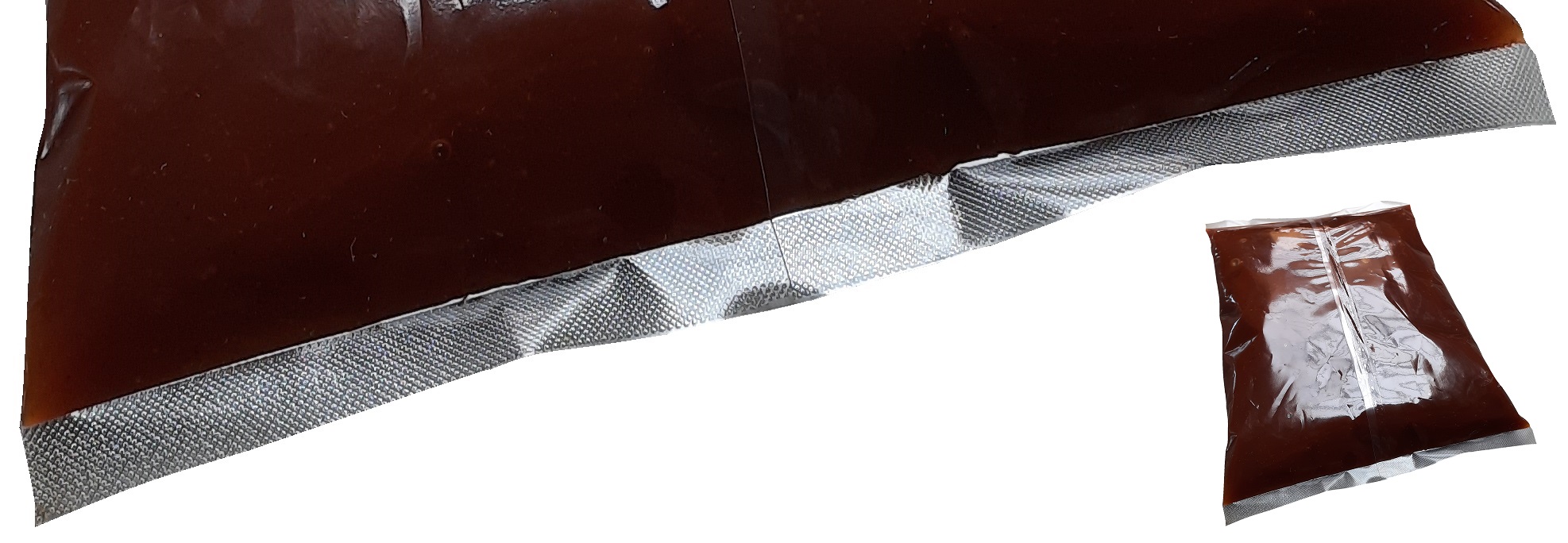

New, compostable and recyclable packaging materials place great demands on the processing machine.

Various customers from the food industry have already tested sustainable packaging materials on GKS machines under production conditions and agree: GKS packaging machines are convincing when processing these packaging materials.

In the laboratories, the produced packs are now subjected to best before date tests.

Newsletter IV / 22

Packaging Machines

A large, 10-lane, 4-side-seal sachet machine type FB-L will soon be installed at a well-known major German spice and ketchup manufacturer, where it will complement another small machine and replace two older lines.

Products such as ketchup, mustard, dressings and dips will be produced in sachets of up to 60 g filling weight each. Fully servo-driven, this highly efficient line will produce up to 700 pouches per minute.

During the conceptional phase of the line, attention was equally paid to the output and processability of sustainable packaging materials. As a result, this packaging machine has already proven successfully to process recyclable and compostable packaging materials.

Batch numbers, expiration dates and additional information can be applied onto the sachets by two state-of-the-art, fully integrated 60 W CO2 lasers. Several safety features and guarding guarantee safe operation and maintenance of the system.

Besides safety compliance, the highest hygiene standards have been requested and will be fulfilled. The design of the system allows the entire dosing system, including the filling pipes, to be automatically cleaned (CIP) or sterilised (SIP) without dismantling any components.

Accessories

The new production line will be completed by a secondary packaging system. Produced sachets will be packed into cartons and transferred. An integrated metal detector within the GKS discharging conveyor as well as additional inspection sensorics will permanently check the product quality. From case erecting up to case closing the complete line is interconnected and will operates fully automated.

Sustainability

What sustainability means to us: to protect the environment while simultaneously producing your product safely and gently on our packaging machines.

In our technical centre, we test compostable and recyclable foils together with well-known manufacturers of packaging materials as well as with our customers.

Ultrasonic Sealing

- airless pouches for particularly types of greasy products or for products with solid ingredients such as BBQ-sauce, salsa or meat sauce and similar

- specially developed combination of low- and high-frequency displacement of product residues from the sealing area

- temperature independent sealing: sealing achieved by vibration and generated heat due to internal friction

- sealing tools remain cool

- 100 % reproduceable sealing results

- extremely good sealing-quality and very wide sealing width

- no sticking of the produced pouches to the sealing tools

- extremely efficient and production reliable

Charging Columns

In cooperation with Elli Group GmbH, a subsidiary of Volkswagen Group Charging GmbH, and the engineering office Wolfgang Müller, a charging column for electric cars was developed.

The technical realization and manufacturing of the charging column was realised by GKS and presented to the Volkswagen board of directors in Wolfsburg at the end of September 2022.

Impressions of the GKS In-House Exhibition in March 2020 - Highlights and Topics

Sachet making with our 4-Side-Seal Sachet Machine FB 330

Our guests could see the latest generation of our best seller live in action. Equipped with two types of dosing for different media, this machine also produces bags filled with liquid and powder as a special highlight, thus demonstrating the versatility of our packaging systems.

Pouch making with our Vertical Pouch Packaging Machine SB 800

On our SB 800 underfloor filling is carried out completely free from residual air. A preservation of the product can thus be realized without gassing. The product shelf life is increased without the use of additives during filling.

Product developments / innovations

- novel filling tube systems

- innovative dosing technologies

Impressions of our first GKS In-House Exhibition in June 2019

We can look back on our completely successful first GKS in-house exhibition in Arnsdorf with a lot of positive feedback and good impressions for our visitors.

Our guests had the opportunity to participate live in machine demonstrations with test materials and to inform themselves about our numerous dosing variants. For example, dosing exhibits for low- and high-viscous liquids, but also powder and granule products, could be viewed and discussed.

Sachet making with our 4-Side-Seal Sachet Machine FB 640 including swab processing

The high-performance machine FB 640 with wipe-folding unit meets the latest international criteria in terms of ergonomics and clean design. Applications with this machine are thus particularly interesting for our customers in the household, chemical and pharmaceutical industries.

Pouch making with our Vertical Pouch Packaging Machine SB 800

On our SB 800 underfloor filling is carried out completely free from residual air. A preservation of the product can thus be realized without gassing. The product shelf life is increased without the use of additives during filling.

Product Developments / Innovations

The following topics were visited and discussed:

- 12-lane double piston pump technology with CIP as well as SIP application

- fully servo-driven 10-lane vertical auger dosing

- ball valve pumps

- various filling tube techniques also with special nozzles for problematic products