Dosing Systems for Liquid Products

For the dosing of your liquid products, we offer latest dosing systems designed according to current hygienic requirements. GKS high-performance dosing systems are certainly tailored to the specific needs and products of our customers.

We will be happy to advise you in order to jointly determine the optimum dosing solution.

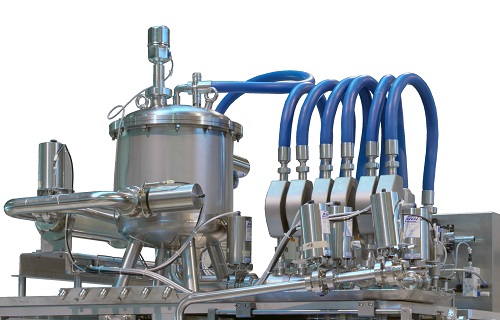

Rotary Valve Pump

Brief Description

- particularly suited for products with medium viscosity

- 2 to 12-lane versions available

- dosing volume infinitely adjustable via HMI

- suck-back capability

- recipe management for all settings

- individual rotary valves with special slide coat

- powerful design of dosing drives

- state-of-the-art control technology, easy to operate via HMI

- product tank with automatic filling level control

- all parts in contact with the product are made of high-grade stainless steel approved for contact with food

- use of seals approved for contact with food (FDA-compliant or comparable)

Variants / Options

- hot-fill applicable

- stirrer(s) in product tank

- CIP/SIP cleaning of dosing system fully automatic without dismantling, cleaning routine configurable and memorizable

- individual servo drives for each lane for small filling volumes and highest accuracy

- combinable with laminar-flow-system

- ATEX version

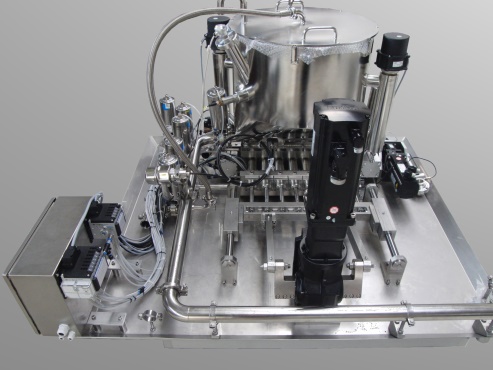

Ball Valve Pump

Brief Description

- particularly suited for products with low viscosity

- 1 to 16-lane versions available

- individually self-sucking

- separate products for each pump / lane possible

- suck-back capability

- simple and compact construction

- dosing volume infinitely adjustable (mechanically)

- drive by common servodrive

- all parts in contact with the product are made of high-grade stainless steel approved for contact with food

- use of seals approved for contact with food (FDA-compliant or comparable)

- simple maintenance

Variants / Options

- different sizes, dependent on filling range

- also possible on separate mobile trolley

- CIP/SIP cleaning of dosing system fully automatic without dismantling, cleaning routine configurable and memorizable

- combinable with laminar-flow-system

- ATEX version

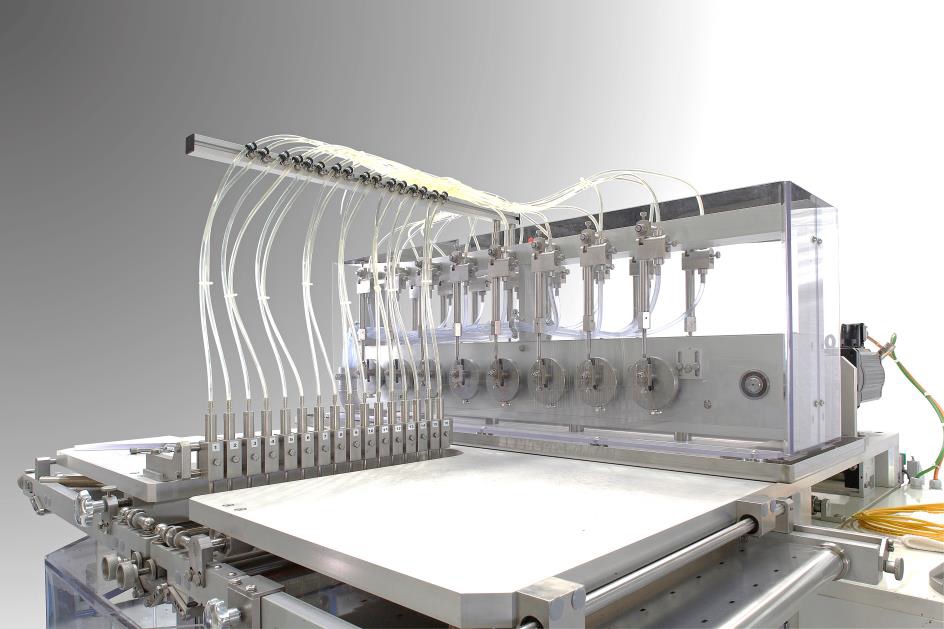

Diaphragm Valve Pump

Brief Description

- particularly suited for products with low viscosity and for abrasive products

- 2 to 12-lane versions available

- dosing volume infinitely adjustable via HMI

- suck-back capability

- recipe management for all settings

- powerful design of dosing drives

- state-of-the-art control technology, easy to operate via HMI

- product tank with automatic filling level control

- all parts in contact with the product are made of high-grade stainless steel approved for contact with food

- use of seals approved for contact with food (FDA-compliant or comparable)

- low maintenance

Variants / Options

- hot-fill applicable

- stirrer(s) in product tank

- CIP/SIP cleaning of dosing system fully automatic without dismantling, cleaning routine configurable and memorizable

- individual servo drives for each lane for little filling volumes and highest accuracy

- combinable with laminar-flow-system

- ATEX version

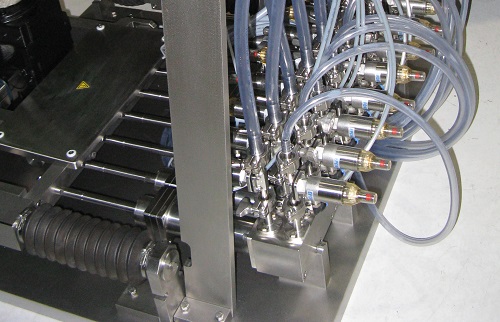

Pressure Tank Dosing

Brief Description

- particularly suited for products with medium viscosity and high speed

- suitable for food and pharmaceutical products

- only in combination with closable filling tubes

- 1 to 12-lane versions available

- dosing volume infinitely adjustable via HMI

- recipe management for all settings

- settings individually adjustable per lane

- state-of-the-art control technology, easy to operate via HMI

- product tank with automatic filling level control

- all parts in contact with the product are made of high-grade stainless steel approved for contact with food

- use of seals approved for contact with food (FDA-compliant or comparable)

- very low wear due to only a few moving parts

Variants / Options

- hot-fill applicable

- stirrer(s) in product tank

- CIP/SIP cleaning of dosing system fully automatic without dismantling, cleaning routine configurable and memorizable

- combinable with laminar-flow-system

- ATEX version